Stealkey Customs

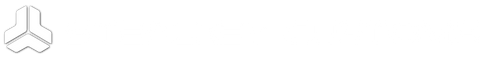

SC CenPro AM5 Plexi D-RGB

Ready to ship 1-3 days

Choose options

Ready to ship 1-3 days

Ready to ship 1-3 days

Details

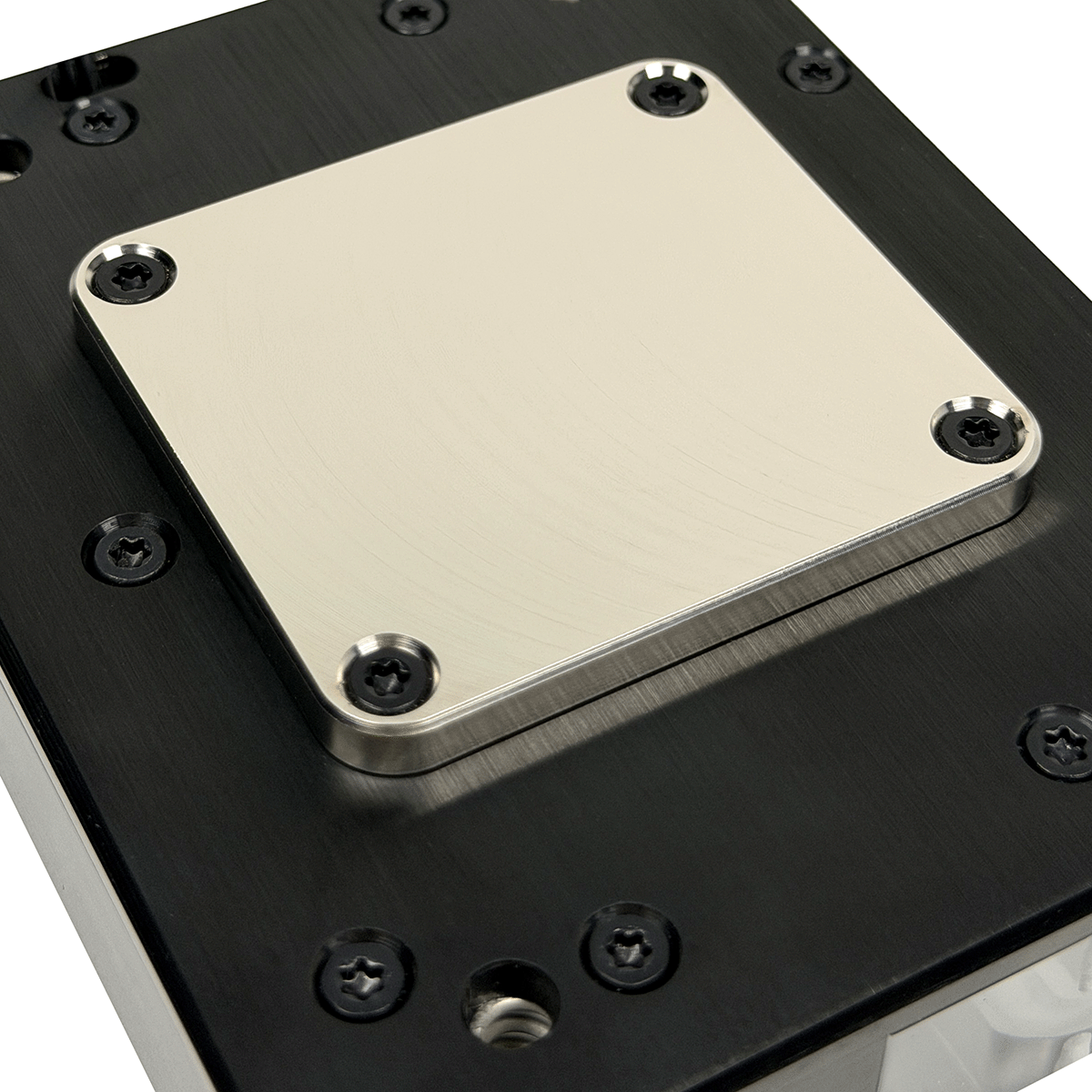

The SC CenPro AM5 Plexi D-RGB is a high-end CPU water block specifically developed for the AMD AM5 platform. It is designed for PC enthusiasts, modders, and performance users who expect uncompromising cooling performance, premium materials, and a modern design.

Technology & Performance of the CPU Water Block

The CenPro combines the best technologies on the market into a superior overall solution. At the heart of its thermal performance lies a high-precision microstructure made up of 68 copper fins, each only 0.2 mm thick, embedded within an area of just 27 x 24 mm. These microfins increase the active cooling surface to approximately 6,460 mm², maximizing heat transfer from the heat spreader into the coolant.

This microstructure is complemented by a jet plate that directs the coolant at high velocity precisely onto the thermal hotspot of the CPU. This focused flow creates increased local pressure, significantly improving heat transfer. At the same time, the optimized nozzle design minimizes flow resistance for maximum cooling performance at minimal flow restriction.

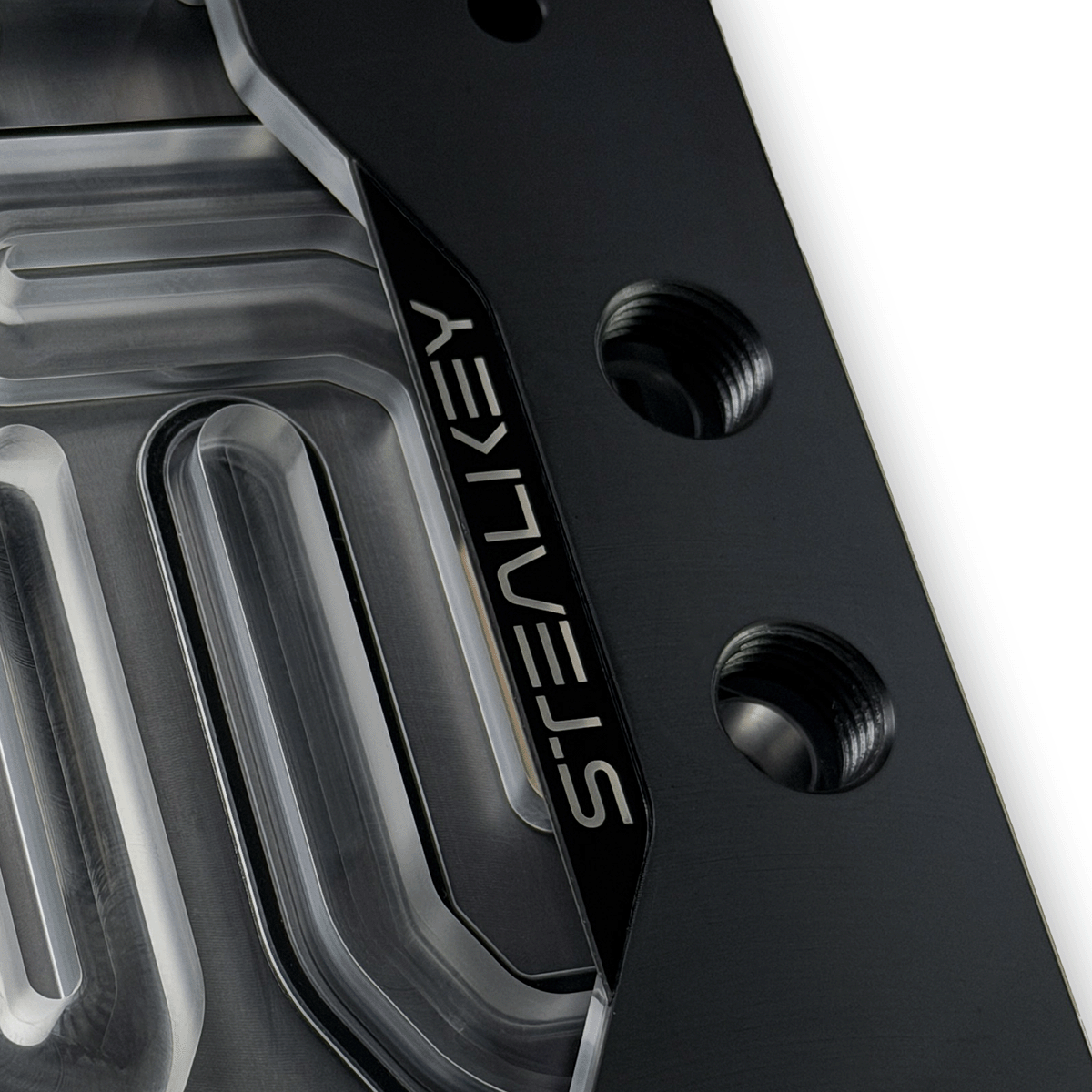

The CenPro completely covers the CPU’s integrated heat spreader (IHS) and ensures optimal thermal contact through even mounting pressure — even when the dies under the heat spreader are unevenly distributed.

Precision in Material and Manufacturing

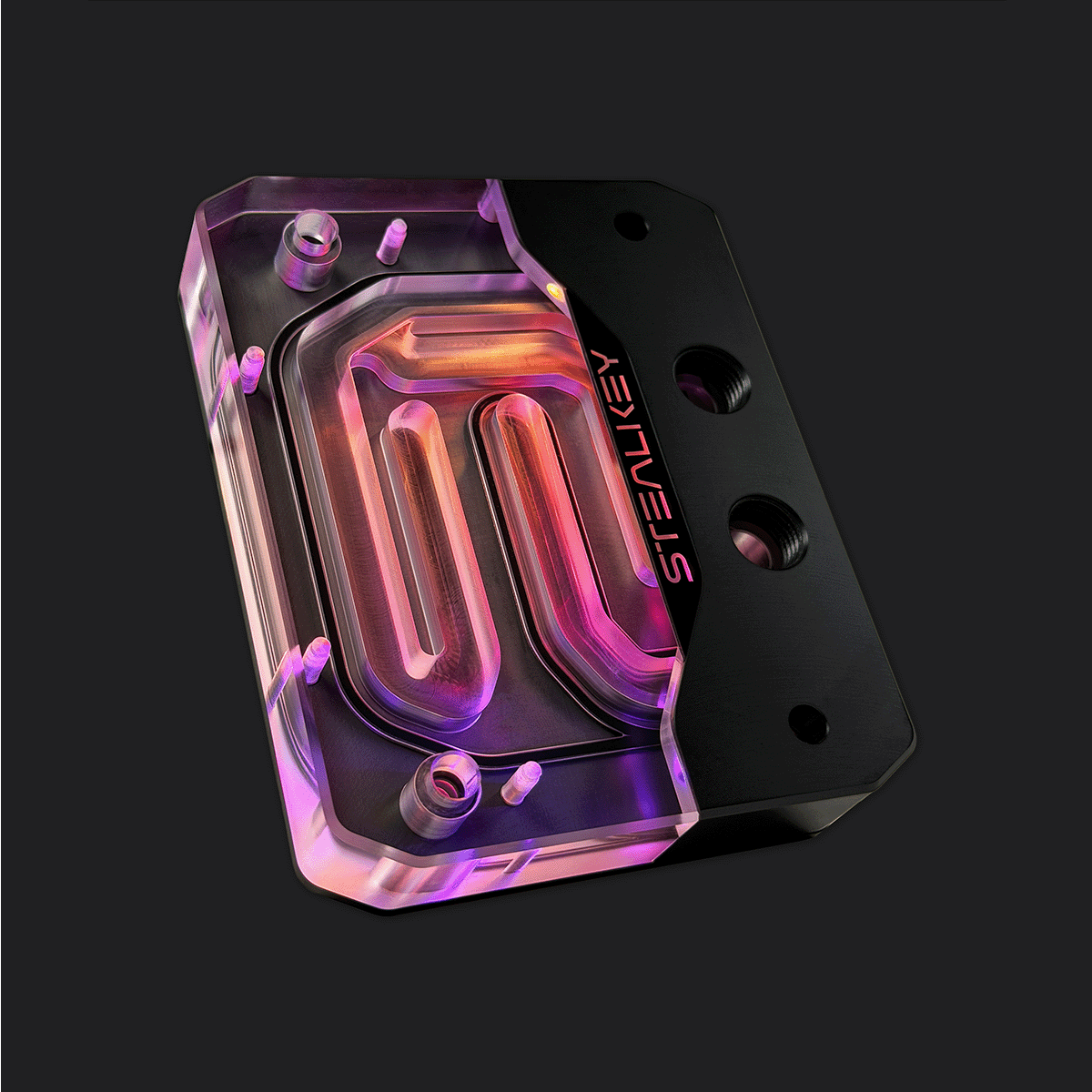

The CNC-machined top made from cast acrylic (PMMA) provides a clear view of the internal cooling structure — also thanks to the ports being positioned on the right-hand side of the CenPro. The terminal is made of CNC-milled acetal, a particularly durable material ideal for the IN & OUT ports of the block.

Easy Mounting System for the AM5 CPU Water Block

The custom-developed Safety-Easy-Mounting-System utilizes the existing AMD motherboard backplate for simple and secure installation. Four included “SC CenPro Distance Bolts” are screwed onto the board and ensure perfect alignment through a fixed stop mechanism. The block is then placed on top and evenly tensioned using integrated springs and “SC CenPro Cylinderhead Nuts.” The risk of over-tightening or damaging the CPU or motherboard is completely eliminated.

Optimized for Custom Loops

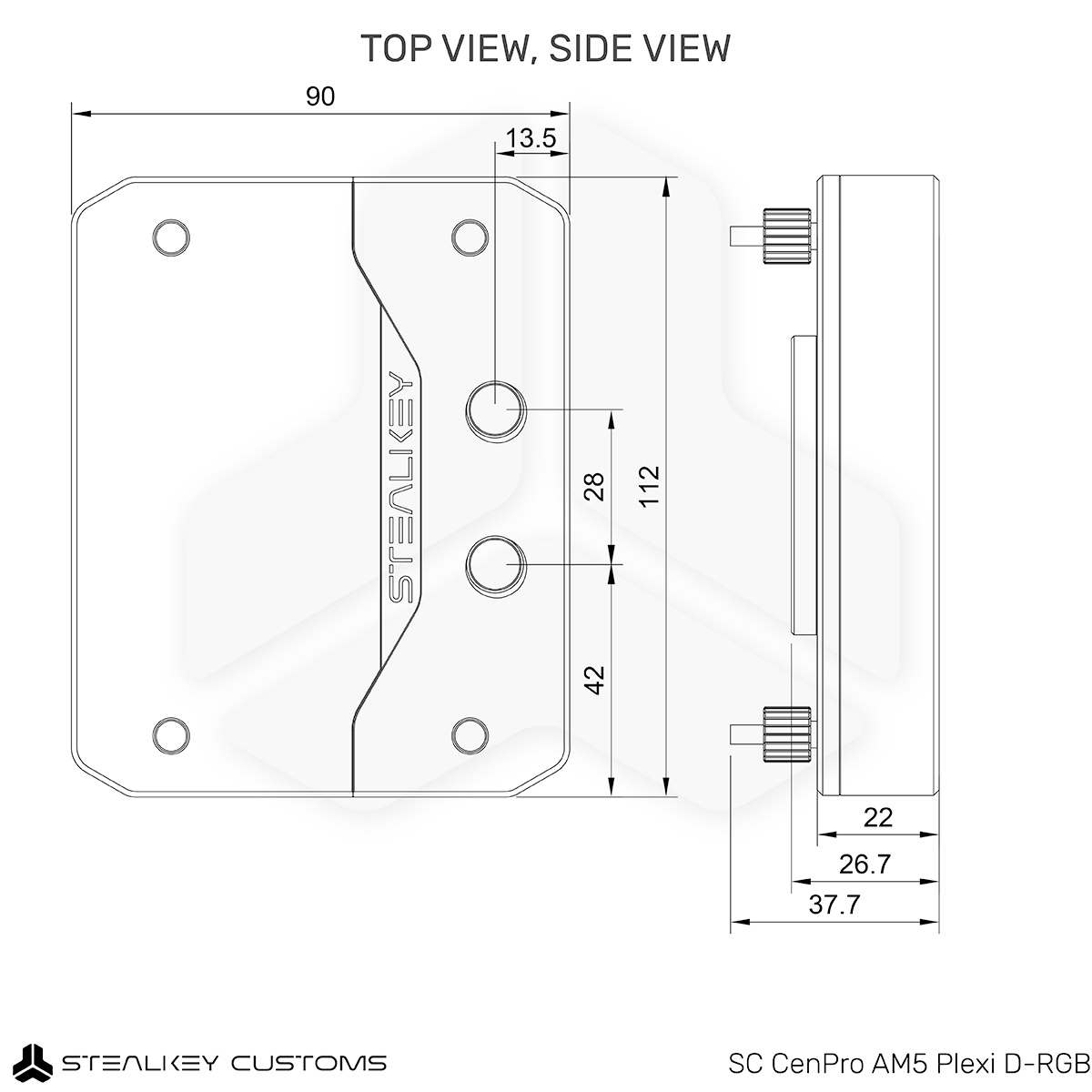

With a port spacing of 28 mm, the CenPro fits perfectly with our in-house distro plates and is ideal for demanding custom-loop setups. The modular product architecture with 7-mm port spacing increments — a well-established industry standard we did not invent but adopted for its technical benefits — simplifies loop planning, reduces tube bending, and ensures a clean, harmonious alignment within the build.

D-RGB Lighting

The terminal houses a D-RGB lighting system with 9 individually addressable LEDs. A projecting diffuser element ensures an even, brilliant light distribution. The block is fully compatible with all major motherboard manufacturers’ ARGB standards (5V, 3-pin). Installation is straightforward via the standardized pin layout.

![]()

Technical Specifications of the CPU Water Block

- Fin thickness: 0.2 mm

- Fin spacing: 0.2 mm

- Top material: Acrylic GS (PMMA) and Acetal

- Baseplate material: Nickel-plated copper

- Weight: 620 g

- Seals: EPDM

- Port spacing: 28 mm

- Dimensions (W x H x D): 112 x 90 x 22.7 mm

- D-RGB cable length: 500 mm

- D-RGB connector: 3-pin 5V digital LED header

- Ports: 2 x G1/4” threads

CPU Socket Compatibility

- AMD AM5

Scope of Delivery

- 1x SC CenPro AM5 Plexi D-RGB

- 4x SC CenPro Distance Bolts

- 4x SC CenPro Cylinderhead Nuts

- 1x 2.5 mm hex key

- 1x Polartherm by Thermal Grizzly X-10 thermal paste, 2 g

Made in Germany

Information

Important Notes for Your Water Cooling System

- No aluminum: Do not use this component with aluminum parts where the coolant comes into direct contact with aluminum.

- Use the right coolant: We recommend special cooling fluids that contain corrosion inhibitors and are free of particles that could clog the loop.

- Leak testing: Test the entire cooling system for leaks for at least one hour using an air pressure tester before filling it with coolant.

- First hours of operation: Inspect the system regularly for leaks during the first 24 hours after filling.

- Do not use alcohol-based cleaning agents or solvents to clean the water block, as these can damage the acrylic.